Drives

Drives

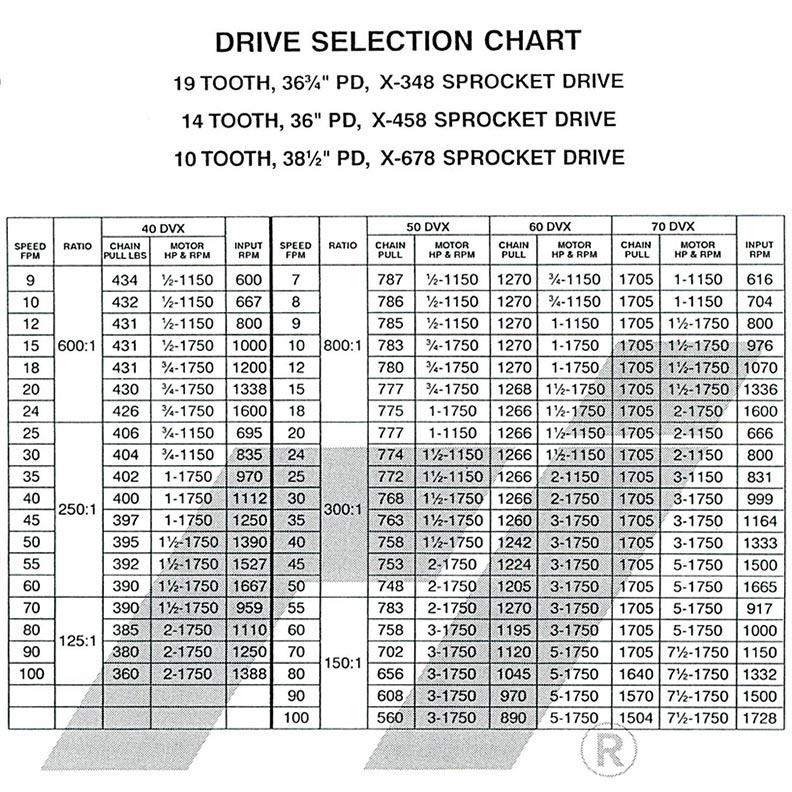

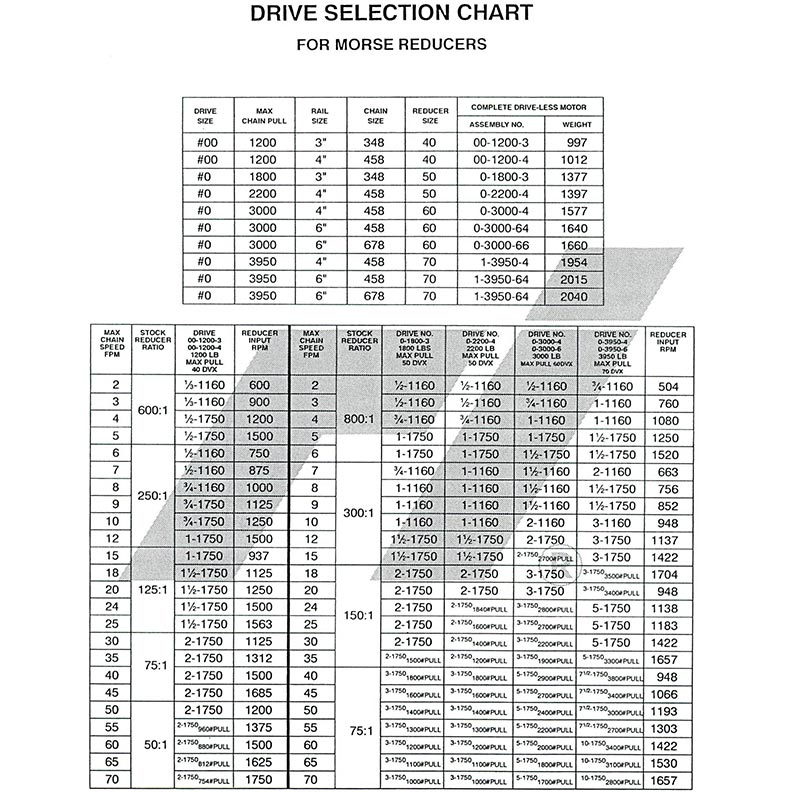

Rapid Overhead Power Chain Drives are available in two general types, the caterpillar drive and the sprocket drive, and is one of the most important components of an overhead conveyor system component. In addition to powering the rivet-less chain, the drive governs the speed of the chain and thus the rate of production. The selection of the proper type of drive and size, as well as gear ratio of the speed reducer, is essential to the design of the system.

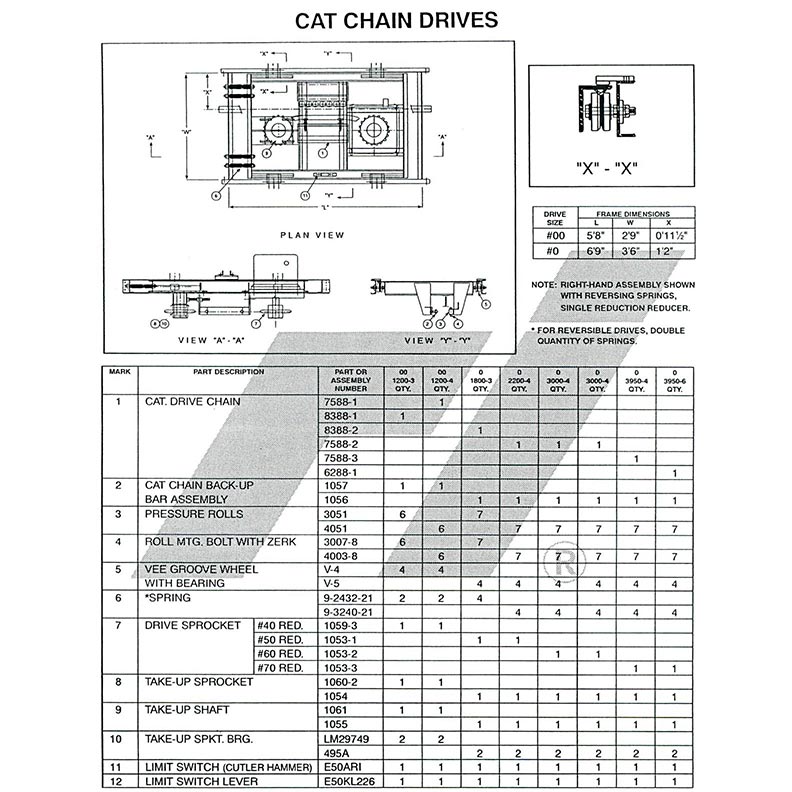

Caterpillar Drives

Stationary caterpillar drives are located on a straight run of the track at a high point in the conveyor system. The drive must pull, not push, the power chain and attachment components are mounted on the main drive frame. This type of drive requires an external overload protection device, i.e. shear pin hub, current limiting device, etc.

Floating caterpillar drives incorporate a system of rollers supporting the drive frame within an enclosed steel stationary frame. The advantage of the floating drive is that, through the use of limit switches for overload protection, the replacement of shear pins when the drive is overloaded is no longer necessary. Floating Caterpillar Drives are available in the same capacity and ratings as Stationary Caterpillar Drives.

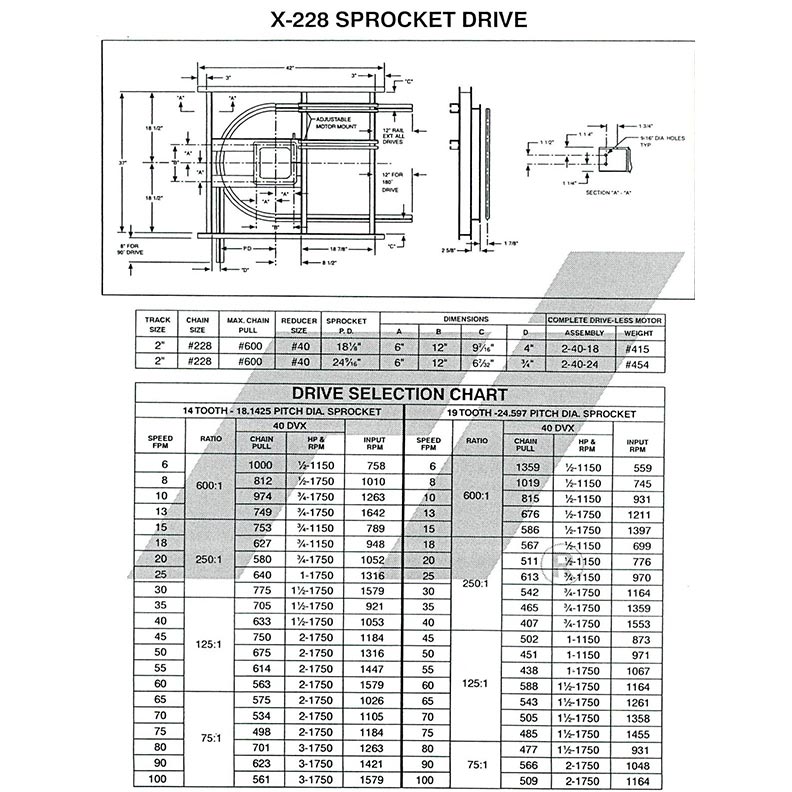

Sprocket Drives

A Sprocket Drive utilizes a sprocket with an integral shear pin hub which engages and drives the power chain of an overhead conveyor system. For use in horizontal turns, a sprocket drive requires a 90 degree chain wrap as the minimum with 180 degree chain wraps often used. All components of a sprocket drive are mounted upon a welded steel frame, which, like the caterpillar drive, is installed in the high portion of the overhead conveyor system. The sprocket drive likewise pulls the rivet-less power chain.

Constant speed drives are the simplest and most economic drives when only one conveyor speed is required. Variable speed drives within the ratio of 3 to 1 are used for applications requiring a speed variation of the overhead conveyor system.

Multiple Drives

Wherever the length of or loading on the system results in chain pull greater than the capacity of the chain and drive, multiple drives may be required. Floating caterpillar drives should be used for multiple drive installations to eliminate successive shear pin breakage in the event one drive is overloaded. For recommendations for multiple drive variable speed systems, please contact the Rapid Industries Engineering Department.